Table of Contents

While we can’t prevent explosions and bomb blasts entirely, building owners and other stakeholders can use a number of strategies to reduce the impacts of such events. These strategies, referred to collectively as blast mitigation, can include using specialized materials, considering blast-resistance in building design and using products such as blast shields and walls.

Blast mitigation doesn’t refer to preventing blasts from occurring in the first place. Instead, it deals with minimizing the damage caused by these explosions. The energy of a detonation, including shock waves and sounds waves, as well as flying fragments, can cause damage to structures and injury to people. Blast mitigation is concerned with making buildings resistant to these forces and protecting people and assets from the damage they can cause.

The shock waves created by large blasts, for example, puts extreme pressure on windows that causes them to break and sends shards of glass flying through the air, multiplying the danger of the incident. This only occurs, however, if the window is made with regular glass. Windows made with blast-resistant glass will instead crumble without sending glass flying. Improving the blast resistance characteristics of windows is vital because flying glass is typically the biggest cause of injury in explosions such as vehicle-bombing incidents. In many cases, they can cause up to 70 to 80 percent of the injuries resulting from such an attack.

The industries that use blast mitigation strategies are those with facilities that are most likely to experience a blast and facilities that would sustain the most damage. Often these are the types of buildings that are most likely to be the targets of terrorist attacks or those that deal with substances that have the potential to explode. Example of facilities that utilize blast mitigation techniques include airports, government buildings, large commercial buildings and petrochemical plants.

Organizations develop approaches to blast mitigation by conducting risk analyses of structures and using the data from these evaluations to plan the best methods.

Taking these precautions is crucial to the safety of the people that work in and visit these buildings as well as to protecting the critical assets they house.

Blast Protection Materials

You can use many different materials to mitigate the impacts of blasts. These materials can thicken or reinforce the walls of structures, absorb impact or help catch flying fragments. The right substance for your purposes will depend on what you need to protect and the risks you need to protect it from. Although there are other potential options, here are some of the most common blast protection materials:

- Wire Mesh: Various types of blast mitigation products are made of wire mesh. The metal used for the wires is typically steel. Mitigation products that use wire mesh include blast shields, containment tanks and curtains. Our products, including our blast shields and blast containment tanks, use 5/8-inch galvanized IRWC wire rope.

- Laminated Glass: For windows, organizations can use various laminated glass options to improve blast resistance. The best option is two layers of laminated glass with air space in between. For cost reasons, though, a layer of annealed or tempered glass and a layer of laminated glass with air space in between is often used. The standard recommendation in the U.S. is quarter-inch laminated glass with an interlayer. Interlayers may be made with polyvinyl-butyral (PVB), plasticized PVB, cured resin, aliphatic polyurethane and other materials.

- Window Film: When retrofitting an existing window to improve its blast mitigation properties, organizations often use window film. Applied to the inside of the glass, these films catch will glass fragments if a blast occurs. While not as ideal as laminated glass, window films work well for retrofitting and providing a quick fix. They may require replacement due to damage from UV rays, cleaning and other factors.

- Foam: You can also use advanced polyurethane foam to absorb some of the force of blasts and direct some of the energy away from people or critical equipment. This material, which comes in many different forms, is typically flame-retardant and self-extinguishing and maintains its capabilities under high temperatures.

- Polyurea Coatings: Spray-on polyurea coatings can be applied to virtually any material to enhance its blast mitigation. This product coats the outside of another substance in a rubber-like film that mitigates the force of blasts and helps hold together the substrate it coats. Also sometimes called an elastomer coating, you can apply this product in a layer of a few inches thick to less than one inch thick.

Blast-Proof Building Design

The structural and design elements of a building can also help to mitigate the impacts of blasts. For buildings at risk of experiencing an explosion, the architects and structural engineers need to work, perhaps with a blast mitigation expert, to incorporate strategies into the building’s design.

A critical first step to structural blast protection is identifying the risk level the building faces and the design criteria that must be followed to sufficiently reduce that risk. This requires an understanding of the impacts of the blasts that may occur in or near a building.

One design element that can help in this area is creating a blast perimeter around the facility to protect it from attacks. This can be accomplished by having security screenings for people entering the buildings or its premises as well as checks for packages delivered to the facility. Loading docks that are separate from the building can also reduce the impacts of any dangerous packages. Building designers may also place walls, bollards or other barriers around the building to restrict vehicle access.

Beyond preventing explosives from entering a building, engineers need to consider design elements that minimize the damage a blast would cause and, crucially, prevent it from causing catastrophic failure.

Buildings are often designed with static loads in mind, but blast mitigation requires engineers to consider the structure’s dynamic response to a blast. They must ensure that its framing and the slabs can account for changes in pressure.

The building must also be designed so that it can still stand if one column or wall collapses. Rather than the collapse of one aspect leading to the failure of another, the damages need to be restricted to a single area through redundancy and separation of sections structurally. A blast-resistant design may also call for walls or columns that are larger or thicker than standard so that they can better withstand the force of blasts.

Incorporating these considerations into the design and building process can increase costs and the time it takes to construct a facility, but for buildings that have a high threat level, blast mitigation is a critical factor in the design process.

Blast Mitigation Products

For high-risk structures that need robust protection from the impacts of potential explosions, blast mitigation products are often the most effective solutions. Blast shields, especially those made with heavy-duty steel cables, are often the best choice for containing explosions. Blast shields may also be called blast walls or curtains, depending on how they are used.

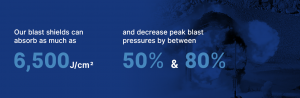

Our blast shields can absorb as much as 6,500В joules per square centimeter (J/cm2) and can decrease peak blast pressures by between 50 and 80 percent. This is crucial as these peak blast pressures are the primary destructive element of blasts. These capabilities enable our blast shields to keep the majority of a blast contained to a single area and prevent the impacts from spreading.

LEARN MORE ABOUT OUR BLAST SHIELDS

Because these shields are made of tightly woven steel cables, they can also block a large percentage of the fragments that may be produced by an explosion but won’t trap dangerous fumes. Unlike some other products, steel cable blast shields contain shrapnel and reduce its velocity rather than redirecting it.

Additionally, our blast shields are fire-resistant and can stop fires from spreading to areas outside the shield.

Blast shields have several advantages over other types of barriers. Walls placed to expand the perimeter can move the blast risk farther from the main structure, but they do not contain the blast itself. The event may still injure people within the perimeter, and if a detonation at the boundary is large enough, its force may still reach the main building and cause damage.

Protections such as concrete walls may also fragment and cause further destruction and injury. Because of the flexible design of blast shields, they will not break apart during explosions and can still provide protection even after being exposed to large-scale blasts.

Using a Blast Shield

TM International blast shields feature a flexible, modular design that makes it easy to set them up according to the demands of various situations. They’re also lightweight and easy to transport while still providing robust protection. You can set them up temporarily for security at a one-time event or make them a permanent protective measure at a facility.

Our blast shields come in panels that you can use individually or combine to cover a larger area. Users often hang them like a curtain over an opening or an area with windows, set them up as walls or cover a ceiling or roof with them. Our SafePass blast shield creates an enclosed space at a checkpoint to contain potential detonations.

SEE OUR BLAST SHIELD IN ACTION

You can place blast shields against building facades to protect the structure or set them up near the perimeter of a facility. Blast shield roof protection systems can protect a structure and the people inside it from missile attacks and other blasts that come from above. You can also hang them along the open spaces of parking garages to prevent explosions from damaging buildings outside of the garage. If a garage is built separately from the main facility, this can be especially useful for reducing damage.

Blast shields are important for petrochemical and manufacturing facilities as well as research labs that have high risks for explosions to the materials they handle. Placing a blast shield around an area where potentially explosive substances are stored can help to reduce the damage that can occur in an accident.

Facilities with industrial boilers can also use blast shields to protect people and assets. A release of pressure from an industrial boiler can be extremely damaging, but a blast shield system can contain a significant portion of this impact. Blast shields can be placed on the walls or flooring in a boiler room to protect the foundation from blast impacts.

Blast Mitigation Best Practices

Blast mitigation is becoming an increasingly important concern for many different types of organizations. For those that work with hazardous materials or could be the victim of a terrorist attack, it’s especially vital. To help protect your facilities and assets, as well as people, from the impacts of blasts, use these practices:

- Make Security a Priority From the Beginning: Safety and security, including blast mitigation, should be a central consideration from the beginning of any planning processing. Whether you’re establishing a new organization or building a new facility, make security an integral part of your design process. If you have an older building that doesn’t meet security standards, consider changes you can make to improve safety.

- Conduct a Risk Assessment: To better understand the steps you need to take to mitigate blasts, conduct a risk assessment. This involves identifying the potential threats and the damage that potential blasts might cause. This risk assessment will give you the information you need to determine the best course of action for protecting buildings from blasts.

- Consider Blast Mitigation in Building Design: If you’re designing a new building for which the threat level is high, blast mitigation should play a central role in the design of the building. The architect and design engineer should work closely with a blast mitigation expert to design the building and its perimeter in a way that minimizes the damage that a detonation would cause.

- Use the Right Materials: The materials you use for your building and infrastructure are another critical consideration. Not only can some materials withstand blast impacts better than others, but the materials used can either worsen the impact of a blast or reduce it. Some materials will shatter and send debris flying at dangerous speeds, while others can absorb some of the force of an explosion.

- Use Blast Mitigation Products: For advanced protection of your building, assets and people, use products designed specifically for blast mitigation. Make sure that the materials and types of products you use fit your needs. You can also customize the size, placement and design of many of these products to make them more effective for your specific situation.

- Implement Security Processes: Security processes can also help protect your organization from explosions. Establishing a safe perimeter and screening people and deliveries before they enter can greatly reduce risk when coupled with blast mitigation strategies. Conduct background checks on new employees and perhaps even those who will be visiting your facility.

Blast Shields From TM International

The risk of blasts due to either accidents or intentional acts is something that we cannot afford to ignore. Making blast mitigation a priority and following these practices can greatly help to reduce risks.

TM International offers products that can be a vital part of your blast mitigation strategy. Our durable, customizable, highly effective blast mitigation products can significantly reduce the damage that an explosion could cause. For more information about how our blast shields and the other products we offer can help reduce risks for your organization, contact us or request a quote today.