Explosives present inherent risks, and blast mitigation solutions can prevent harm, save lives and protect structures. Blasting is used in many industries, such as mining and construction. Blast protection is used when blasting is used as a construction or demolition technique, as well as in airports and military and government applications, where safety is top priority.

Understanding the forces at play during a blast is crucial for ensuring the safety of personnel and infrastructure. Once you understand blast pressure ratings, you can implement solutions to mitigate specific blast effects.

What Is Blast Pressure?

Blast pressure is the instantaneous rise in air pressure above the normal atmospheric pressure caused by the rapid expansion of gases from an explosion. The more precise technical term for blast pressure is blast overpressure, though blast pressure is widely used as shorthand. When an explosion occurs, it generates a rapidly expanding shockwave that pushes the air with extra force. Typical atmospheric pressure is around 14.7 pounds per square inch (psi) at sea level, so any pressure created by an explosion above that baseline is classified as overpressure.

Key Terminology Explained

While numerous commercial blasting industry terms may be useful to technical professionals, here are some key terms related explicitly to blast pressure:

- Peak overpressure: The peak overpressure of a blast wave is the maximum pressure increase from the explosion.

- Positive phase duration: After the initial peak pressure, the pressure gradually decreases back to normal atmospheric pressure. The time it takes for the pressure to return to normal is the positive phase duration.

- Negative phase: Following the positive phase, there is a brief period where pressure dips below normal, creating suction.

- Impulse: Impulse is the total force applied by the blast wave over time.

- Incident and reflected pressure: When a blast wave encounters a surface, the incident pressure is the pressure exerted by the wave as it initially arrives. The reflected pressure is the increased pressure that results from the wave bouncing off the surface, creating a higher pressure than the initial incident pressure.

Measurement Units

Understanding overpressure measurement units is critical for interpreting material properties and choosing and designing effective blast mitigation systems. Each unit provides a different perspective on the forces at play during an explosion:

- Pounds per square inch: Psi is a unit of pressure that measures the amount of force exerted on an area of 1 square inch. Blast overpressure values are often given in psi. For example, knowing that a potential blast could generate 5 psi of overpressure allows engineers to select building materials and protective barriers that can withstand at least that level of force.

- Kilopascals: Kilopascals (kPa) are the metric unit of pressure. One psi is equal to 6.895 kPa. kPa is one of the standard units used in many international engineering and scientific publications.

- Bar: A bar is a metric unit of pressure equal to 100 kPa or 14.5 psi. Bars are often used in industrial settings and in specifications for heavy-duty equipment.

- Joules/cm²: Joules per centimeter squared measure the amount of energy a material can absorb per unit area. This unit quantifies how much energy a material can absorb before failing, which is crucial for selecting materials that can effectively mitigate blast effects. It’s important to note that this value is highly dependent on the specific material being tested.

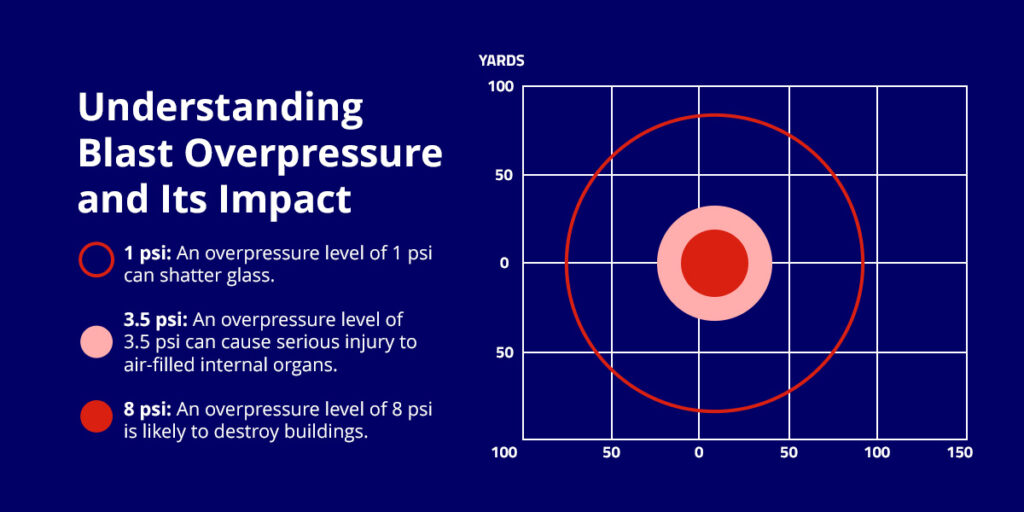

Understanding Blast Overpressure and Its Impact

The bigger the explosion, the more damaging the pressure wave. When technical professionals understand blast ratings, they can put precautions in place to mitigate the expected blast effects. Numerous industries use professional blast-mitigation barriers, and blast ratings can help organizations make informed decisions about what they require. For example, here are some default overpressure values that could inform blast-mitigation strategies:

- 1 psi: An overpressure level of 1 psi can shatter glass.

- 3.5 psi: An overpressure level of 3.5 psi can cause serious injury to air-filled internal organs.

- 8 psi: An overpressure level of 8 psi is likely to destroy buildings.

Types of Blast Injuries

To understand why blast ratings are essential, it’s important to know how blast overpressure affects the human body and structures. There are different types of blast injuries, including:

- Primary: A primary blast injury is caused by a blast wave moving through the body. Only high-order explosives can cause a blast wave, so primary blast injuries are most commonly associated with high-order explosives. The direct impact of a blast wave can damage the body, primarily the air-filled organs.

- Secondary: Injuries caused by debris propelled by an explosion are classified as secondary blast injuries. This category accounts for most explosion-related injuries and can be caused by debris from the explosive device or the materials surrounding the device during the explosion.

- Tertiary: When the blast wind of an explosion displaces a person through the air, causing harm, these are called tertiary blast injuries.

- Quaternary: All injuries not included in the primary, secondary or tertiary categories are classified as quaternary. These injuries can include inhalation, radiation and burn injuries, as well as mental health issues.

The higher the blast rating, the more precautions must be taken to protect against each type of blast injury.

The Role of Blast Protection in Industrial Safety

Understanding construction blast risks is important because different types of blast protection are superior in specific scenarios. In industrial settings, adhering to explosion protection standards is crucial for minimizing risks.

Types of Blast-Mitigation Barriers

Different blast protection products can effectively mitigate the risk of injury. Ensure your supplier has implemented extensive product testing for increased protection and efficacy. Here are some commonly used blast-mitigation barriers:

- Blast mats: In industries such as mining and construction, blast mats are common at jobsites and in quarries. These strong, flexible, dense products limit noise, dust, flyrock and other debris. Blast mats can also contain some of the vibrations that might otherwise damage surrounding structures or people.

- Blast walls and barriers: Safety personnel can also reduce explosive overpressure and debris by using a blast wall as a protective barrier, especially against heavy blasts. Understanding blast wall pressure testing is essential for selecting the right barrier.

- Blast shields: SafePass blast shields are covered tunnels that can protect pipelines and infrastructure when construction teams use blasting instead of or alongside digging. These shields can also be used for fire and explosion protection in checkpoint lines. Depending on your needs, you might choose products for specific uses, such as blast-resistant shields for roofing, a boiler explosion blast protection shield or products designed especially for other applications.

- Blast containment tank: Steel blast containment tanks can be used for emergency containment of explosive devices. These devices are most commonly used by bomb squads, police, military and private security for their effective blast containment performance.

Benefits of Industrial Blast Protection

Implementing effective blast protection measures is essential. The benefits of high-quality blast-mitigation barriers include:

- Operational continuity: Blast protection helps to maintain operational continuity by minimizing damage to equipment and infrastructure.

- Employee safety: Blast protection can safeguard employees from injury or death in the event of an explosion. Blast barriers are central to minimizing construction injuries and preserving workers’ well-being.

- Regulatory compliance: Implementing blast protection measures helps companies comply with OSHA regulations for blasting and other industry standards.

Explore TM International, LLC for Protection Against Pressure

Understanding blast pressure ratings is critical to proactive safety management in various industries. By knowing the key terminology, measurement units and potential impacts of blast overpressure, technical professionals can use informed blast protection calculations to make risk assessment and mitigation decisions. To effectively mitigate these risks, it’s essential to partner with a trusted provider of blast-mitigation solutions.

TM International, LLC is a leader in the explosive safety industry and is committed to maximizing protection with effective blast-mitigation barriers. Our products meet stringent blast mitigation specifications and offer peak blast pressure reduction to safeguard people, structures and equipment. Many of our products are also economical, environmentally friendly and recyclable. We pride ourselves on exceptional customer service and can help you find the right equipment for your needs.

Explore our products or contact us for more information.